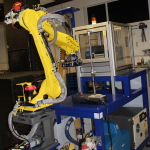

Robotic labelling workplace ARP

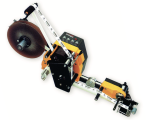

Application robotic workplace is a solution designed to label the product on its front and side. This makes the FANUC robotic system with the highest precision. The Fanuc ARC Mate robotic arm performs motion in the area along designated paths to provide basic activity. The label is printed on the stack with information obtained from the IS of the customer, followed by hot melt bonding and by the controlled movement is placed at the desired locations.

The duty cycle is initiated by the initial signal received by the ARP from the transport line. The signal is generated when the sensor detects that the product is in the position for labeling. ARP is equipped with a robotic system that provides the following basic activities with ARC PLC:

Remove the printed label from the printer output slot on the face of the application head

Holding the label on the application head

Apply hot melt adhesive on the label

Sticking labels to the designated product room

View detail